Blog

How To Fix Briggs And Stratton Pressure Washer Pump

If you own a Briggs and Stratton pressure washer, you know how important it is to keep the pump in good working condition. The pump is the heart of your pressure washer, and without it, you won’t be able to clean efficiently. However, like any mechanical part, the pump can develop problems over time. Fortunately, many common pump issues can be fixed easily without the need for professional help.

One common problem with Briggs and Stratton pressure washer pumps is low water pressure. If you’re experiencing low water pressure, the first thing to check is the inlet hose. Make sure it’s not kinked or blocked, as this can restrict water flow. You should also check the pump’s inlet valve to ensure it’s not clogged with debris. Cleaning or replacing the valve can often solve the issue and restore your pressure washer’s performance.

Another common issue is a leaking pump. If you notice water leaking from the pump, first check the pump seals and gaskets. Over time, these can wear out and need to be replaced. Additionally, check the connections between the pump and the pressure hose for any loose fittings. Tightening them can often stop the leak. If the leaking persists, you may need to replace the pump altogether.

In some cases, the pump may fail to build pressure. This can be caused by a variety of issues, including a worn-out pressure relief valve or a damaged seal. Checking and replacing these parts, if needed, can usually solve the problem. If the pump is still not building pressure, it may be necessary to replace the entire pump assembly.

By following these simple troubleshooting steps, you can keep your Briggs and Stratton pressure washer pump in top shape and ensure efficient cleaning for years to come. Remember to always consult the manufacturer’s manual for specific instructions and safety guidelines.

Common Issues with Briggs and Stratton Pressure Washer Pump

Briggs and Stratton pressure washer pumps are known for their reliability and power, but like any mechanical device, they can encounter issues over time. Here are some common problems you may encounter with your Briggs and Stratton pressure washer pump:

- No or low pressure: If your pressure washer pump is not producing any or low pressure, it could be due to a clogged nozzle, a worn-out pump seal, or a malfunctioning unloader valve. Cleaning or replacing the nozzle, replacing the pump seal, or adjusting the unloader valve could resolve the issue.

- Leaks: Leaks in the pressure washer pump can occur due to loose fittings, worn-out seals, or damaged O-rings. Tightening the fittings, replacing the seals or O-rings can help fix the leaks.

- Excessive vibration: Excessive vibration during operation can be caused by a misaligned pump, loose bolts, or unbalanced internal parts. Aligning the pump, tightening the bolts, or balancing the internal parts can help reduce the vibration.

- Loud noise: If your pressure washer pump is making loud noises, it could be due to a loose or damaged component, worn-out bearings, or debris lodged in the pump. Tightening or replacing the component, replacing the bearings, or removing the debris can eliminate the noise.

- Pump not priming: If the pump is not priming properly or at all, it could be due to a clogged inlet valve, air leaks in the pump, or a malfunctioning thermal relief valve. Cleaning the inlet valve, fixing any air leaks, or replacing the thermal relief valve can help resolve the priming issue.

It’s important to regularly inspect and maintain your Briggs and Stratton pressure washer pump to prevent these common issues. Performing routine cleaning, lubrication, and part replacements can help prolong the life of your pressure washer pump and ensure optimal performance.

Determining the Cause of Low Pressure

When your Briggs and Stratton pressure washer pump is not producing enough pressure, there can be several causes for this issue. By systematically checking various components, you can determine the cause and take the appropriate steps to fix the problem.

First, check the water supply. Ensure that the water source is providing a constant flow of water at the correct pressure. Inspect the inlet hose and screen for any obstructions or damage that may restrict the water flow. If necessary, clean or replace the inlet hose and screen to ensure proper water supply.

Next, examine the high-pressure hose for any kinks, leaks, or blockages. A damaged or clogged high-pressure hose can hinder the flow of water, resulting in low pressure. If you identify any issues, repair or replace the high-pressure hose to restore proper water flow.

Inspect the spray gun and wand assembly for any damage or clogs. A faulty spray gun or wand can impede the flow of water and lead to low pressure. Clean or replace the spray gun and wand if needed to resolve this issue.

Check the nozzle for any debris or blockages. Sometimes, dirt or other foreign objects can clog the nozzle, causing low pressure. Clean or replace the nozzle as necessary to ensure proper water flow.

Lastly, assess the pressure washer pump itself. Look for any signs of damage or wear, such as leaks or worn-out seals. A damaged pump can result in low pressure. If you suspect a problem with the pump, consult the manufacturer’s instructions or contact a professional for further assistance.

By carefully inspecting and addressing these potential causes of low pressure in your Briggs and Stratton pressure washer pump, you can effectively diagnose and fix the problem, restoring optimal performance to your equipment.

Repairing Leaks in the Pump

If you notice leaks in your Briggs and Stratton pressure washer pump, it is important to address them promptly to prevent further damage and maintain optimal performance. Here are some steps you can take to repair leaks in the pump:

Determine the Source of the Leak

Before you begin any repairs, you need to determine where the leak is coming from. Inspect the pump thoroughly to identify the source of the leak. Common areas where leaks can occur include the seals, fittings, and valves. Once you have identified the source, you can proceed with the necessary repairs.

Replace Damaged Seals

If the leak is caused by a damaged seal, you will need to replace it. Start by removing the old seal carefully using a seal removal tool or a flat-headed screwdriver. Clean the area around the seal using a mild detergent and water. Then, apply a small amount of lubricant to the new seal before inserting it into the pump. Make sure the seal is properly seated and secure.

Note: It is important to use the correct size and type of seal for your specific pressure washer pump model. Refer to the manufacturer’s instructions or consult a professional if you are unsure.

Tighten Loose Fittings

If the leak is due to loose fittings, you can try tightening them to stop the leak. Use a wrench or pliers to tighten the fittings gently. Be careful not to overtighten, as this can cause damage to the pump. Check for any signs of improvement after tightening the fittings. If the leak persists, you may need to replace the fittings.

Inspect and Clean Valves

Leaking valves can also be a common cause of pump leaks. Inspect the valves for any signs of damage or debris. If there is debris present, clean it using a soft brush or cloth. Make sure the valves move freely and are not stuck, as this can also cause leaks. If a valve is damaged or not functioning properly, it may need to be replaced.

Remember to always follow safety precautions and refer to the manufacturer’s instructions when working on your pressure washer pump. If you are unsure or uncomfortable with performing the repairs yourself, it is recommended to seek professional assistance.

Cleaning Clogged Nozzles and Filters

If you’re experiencing a loss of pressure or irregular spray patterns with your Briggs and Stratton pressure washer, chances are that your nozzles and filters may be clogged. Cleaning them is a fairly simple task that can improve the performance of your pump.

Cleaning Nozzles

Start by removing the nozzle from the pressure washer spray gun. Inspect the nozzle carefully for any signs of debris or dirt accumulation. If there is any clogging, use a small cleaning brush or a pin to remove the dirt from the nozzle. Make sure not to enlarge the nozzle or damage its inner components while cleaning. Rinse the nozzle under running water to remove any residual dirt, and then reinstall it back onto the spray gun.

Cleaning Filters

Most Briggs and Stratton pressure washers have filters that prevent debris from entering and clogging the pump. These filters need regular cleaning to maintain optimum performance. Locate the filter, which is typically located on the water inlet of the pump.

Remove the filter by unscrewing it counter-clockwise or pulling it out, depending on the type of filter used in your pressure washer. Rinse the filter under running water to remove any dirt or debris. You may also use a small cleaning brush to remove stubborn dirt particles.

Inspect the filter carefully for any signs of damage. If the filter is damaged or excessively dirty, replace it with a new one. Make sure to use a filter that is specifically designed for your Briggs and Stratton pressure washer model.

Once the filter has been cleaned or replaced, reinstall it back into the pump, ensuring it is securely tightened. This will prevent any leaks or loss of pressure.

Regularly cleaning the clogged nozzles and filters on your Briggs and Stratton pressure washer will help to maintain its performance and extend its lifespan. This simple maintenance task can save you time and money in the long run, ensuring that your pressure washer is always ready to tackle any cleaning task.

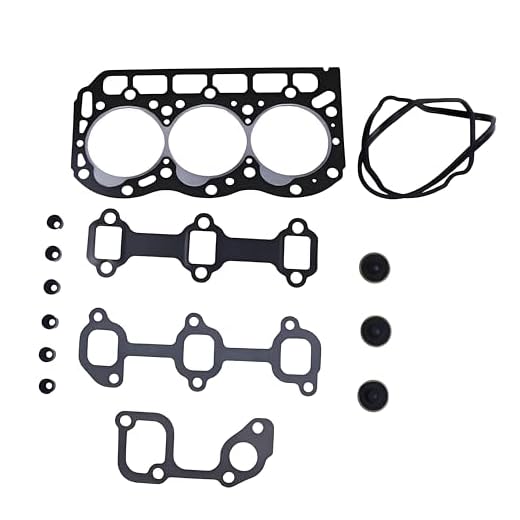

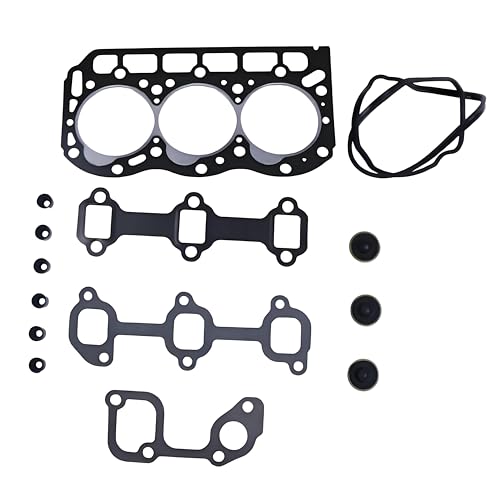

Replacing Worn-out Pump Seals

Over time, the seals in your Briggs and Stratton pressure washer pump can start to wear out, leading to leaks and decreased performance. Fortunately, replacing these worn-out seals is a relatively straightforward process that can be done at home with a few simple tools.

Gather the necessary tools and materials

Before you begin, make sure you have the following tools and materials:

- Replacement pump seals

- Phillips screwdriver

- Flathead screwdriver

- Socket wrench set

- Needle-nose pliers

- Rubber mallet

Remove the pump from the pressure washer

First, turn off the pressure washer and disconnect it from any power source. Next, remove the pump from the pressure washer by unscrewing the bolts or screws that secure it in place. Use your socket wrench set to loosen and remove these fasteners.

Disassemble the pump

Once the pump is removed, carefully disassemble it by removing the screws or bolts that hold the pump housing together. Use your Phillips screwdriver or socket wrench to do this. Keep track of the order in which you remove the components, as you will need to reassemble them later.

Remove the old seals

Locate the worn-out pump seals and use your flathead screwdriver or needle-nose pliers to carefully pry them out of their housing. Be gentle to avoid causing any damage to the pump or other components. Take note of the orientation of the old seals, as the new ones will need to be installed in the same way.

Install the new seals

Take your replacement pump seals and insert them into the housing in the same orientation as the old seals. Ensure that they are securely in place and properly aligned. Use a rubber mallet to gently tap the seals into place, if necessary.

Reassemble the pump

Once the new seals are installed, carefully reassemble the pump in the reverse order of disassembly. Make sure all the screws or bolts are tightened securely. Double-check that all the components are in their proper places before proceeding.

Finally, reattach the pump to the pressure washer by screwing in the bolts or screws that secure it in place. Test your pressure washer to ensure that the new seals have solved the issue of leaks and restored its performance.

By following these steps and replacing the worn-out pump seals, you can prolong the life of your Briggs and Stratton pressure washer and keep it running smoothly for years to come.

Maintaining the Pump for Longevity

Maintaining your Briggs and Stratton pressure washer pump is essential for its longevity and optimal performance. Here are some tips to help you keep your pump in good condition:

1. Regularly Check and Change the Oil

Make sure to check the oil level in the pump regularly and change it as recommended by the manufacturer. Clean and fresh oil helps to lubricate the internal components, reducing friction and prolonging the pump’s life.

2. Inspect and Clean the Inlet Filter

The inlet filter prevents debris from entering the pump and causing damage. Regularly inspect the filter and clean or replace it if necessary. A clogged filter can restrict water flow and put unnecessary strain on the pump.

3. Flush and Clean the Pump

After each use, flush the pump with clean water to remove any dirt, debris, or chemicals that may have accumulated. This helps to prevent clogs and corrosion. Additionally, you can use a pump cleaning solution to remove any built-up residue.

4. Store the Pump Properly

When storing your pressure washer, drain any remaining water from the pump and hoses. Keep it in a dry and protected area to prevent damage caused by freezing temperatures or exposure to sunlight.

By following these maintenance tips, you can ensure that your Briggs and Stratton pressure washer pump remains in good working condition for years to come.

Questions and answers

What could be the reason for low pressure in my Briggs and Stratton pressure washer pump?

There are several possible reasons for low pressure in your pressure washer pump. It could be due to a clogged nozzle, a worn-out pump, a loose or damaged hose, or a problem with the pressure regulating valve. You can try cleaning the nozzle, checking the hose and replacing it if necessary, or adjusting the pressure regulating valve. If none of these steps fix the issue, you may need to replace the pump.

How can I clean the nozzle of my Briggs and Stratton pressure washer pump?

To clean the nozzle of your pressure washer pump, first, turn off the engine and disconnect the spark plug wire to prevent accidental start-up. Then, remove the nozzle from the spray wand and soak it in a cleaning solution, such as vinegar or a specialized nozzle cleaner. Use a small brush or a pin to remove any clogs or debris from the nozzle. Rinse it thoroughly with water before reattaching it to the spray wand. This should help improve the water flow and pressure.

Is it possible to repair a Briggs and Stratton pressure washer pump on my own?

Yes, it is possible to repair a Briggs and Stratton pressure washer pump on your own. However, it depends on the extent of the damage and your mechanical skills. Simple repairs, such as unclogging the nozzle, replacing a worn-out hose, or adjusting the pressure regulating valve, can be done by most people with basic tools. However, more complex repairs, such as replacing the pump or fixing internal parts, may require professional assistance or specialized knowledge. It is important to assess your own abilities and decide whether to attempt the repair yourself or seek professional help.

What are some precautions I should take before repairing my Briggs and Stratton pressure washer pump?

Before repairing your pressure washer pump, there are a few precautions you should take to ensure your safety. First, make sure to turn off the engine and disconnect the spark plug wire to prevent accidental start-up. Wear protective gloves and eye goggles to protect yourself from any potentially harmful chemicals or debris. Follow the manufacturer’s instructions and safety guidelines when working with the pump. Finally, if you are unsure about any step of the repair process, it is better to seek professional help rather than risking further damage or injury.

How often should I perform maintenance on my Briggs and Stratton pressure washer pump?

Regular maintenance is essential to keep your pressure washer pump in good working condition. It is recommended to perform maintenance tasks, such as cleaning the nozzle, checking and tightening hoses, inspecting for leaks or damage, and replacing worn-out parts, at least once a year or after extended periods of use. Additionally, following the manufacturer’s maintenance schedule and guidelines can help prolong the lifespan of your pump and prevent costly repairs in the future.

How do I fix a Briggs and Stratton pressure washer pump that is not working?

If your Briggs and Stratton pressure washer pump is not working, there are a few steps you can take to fix it. First, check the spark plug and replace it if necessary. Next, check the fuel tank and make sure it is not empty. You should also check the air filter and clean or replace it if needed. Finally, check the oil level and add more if necessary.

Recent Posts

-

How To Connect Soap To Honda Pressure Washer

June 28, 2024 -

A To Z Pressure Washing Scam

June 27, 2024 -

How To Pressure Wash Your Home With A Garden Hose

June 27, 2024 -

Where Can I Buy Honda Pressure Washer Parts

June 25, 2024