Blog

Will Flex Tape Work On A Pressure Washer Hose

When it comes to fixing a pressure washer hose, there are many options available on the market. However, one product that has gained a lot of attention is Flex Tape. This innovative tape claims to be able to bond, seal, and repair virtually anything. But the question remains, will Flex Tape work on a pressure washer hose?

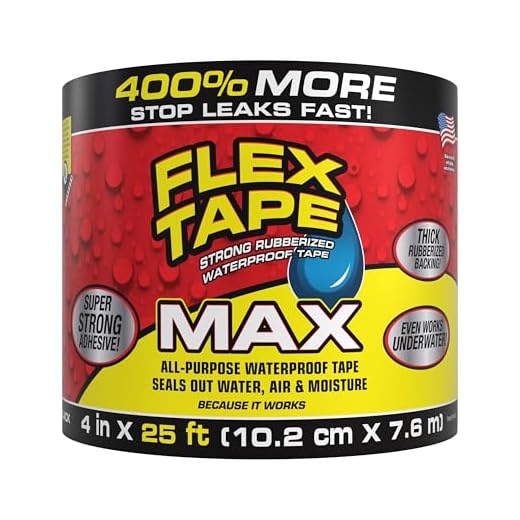

Flex Tape is designed to create a super strong bond that can withstand extreme conditions. The tape is made from a thick, flexible rubber that has a strong adhesive backing. It is also waterproof, making it ideal for repairing hoses that come into contact with water.

The first step in using Flex Tape to repair a pressure washer hose is to clean the surface. Make sure that the hose is completely dry before applying the tape. Once the surface is clean and dry, simply cut a piece of Flex Tape to the desired size and apply it directly to the damaged area. Press down firmly to ensure that the tape creates a strong bond with the hose.

While Flex Tape may be a quick and easy solution for repairing a pressure washer hose, it is important to keep in mind that it is not a permanent fix. Over time, the tape may start to peel or lose its bond, especially if it is exposed to harsh conditions. It is always a good idea to monitor the repaired area and reapply the tape as needed.

Overview

When it comes to fixing a pressure washer hose, Flex Tape can be a valuable tool. This adhesive tape is designed to create a watertight seal and can be used on a variety of surfaces, including rubber, PVC, and metal. However, before attempting to repair a pressure washer hose with Flex Tape, it is important to carefully assess the damage and consider the potential limitations of the tape.

Flex Tape works by bonding to the surface and creating a tight, waterproof seal that can withstand exposure to water and other liquids. It is designed to be durable and long-lasting, making it a popular choice for many repair projects.

Potential Limitations

While Flex Tape can be effective at repairing small to moderate cracks or holes in a pressure washer hose, it may not be suitable for larger or more severe damage. In these cases, it is recommended to replace the hose rather than attempting to fix it with tape. Additionally, it is important to ensure that the hose is properly cleaned and dried before applying the tape for optimal adhesion.

It is also worth noting that Flex Tape may not adhere properly to certain types of hoses or surfaces. It is always a good idea to test a small area of the hose before applying the tape to ensure compatibility and effectiveness.

Proper Application

To apply Flex Tape to a pressure washer hose, start by cutting a piece of tape that is slightly larger than the damaged area. Remove any dirt or debris from the surface of the hose and make sure it is dry. Peel off the backing of the tape and carefully place it over the damaged area, pressing down firmly to ensure proper adhesion. Smooth out any air bubbles or wrinkles, and allow the tape to set for the recommended time before using the pressure washer.

It is important to regularly inspect the repaired area and check for any signs of wear or damage. If the tape begins to peel or lose its effectiveness, it may be necessary to reapply or consider a different repair method.

In conclusion, Flex Tape can be a viable option for repairing a pressure washer hose, but there are some limitations to consider. It is important to properly assess the damage and ensure compatibility before attempting to use Flex Tape. With the proper application and regular inspections, Flex Tape can provide a temporary solution to minor hose repairs.

Discover if Flex Tape is the Solution for Your Pressure Washer Hose

Are you dealing with a leak in your pressure washer hose and wondering if Flex Tape can help? Look no further, as we dive into whether or not Flex Tape is the solution you’ve been searching for.

What is Flex Tape?

Flex Tape is a popular adhesive tape known for its strong adhesive properties and waterproof seal. It is designed to patch, bond, seal, and repair a variety of surfaces and materials. Its versatility has made it a favorite among DIY enthusiasts and professionals alike.

Can Flex Tape Repair a Pressure Washer Hose?

While Flex Tape is incredibly durable and can patch many types of damage, it may not be the best solution for repairing a pressure washer hose. Pressure washer hoses are subjected to incredibly high pressures and can burst if not properly maintained. Flex Tape may not be able to withstand the extreme pressure and could eventually fail, resulting in a potential safety hazard.

Alternative Solutions

If you’re dealing with a leak in your pressure washer hose, it is recommended to replace the hose entirely. Pressure washer hoses are often made of high-strength materials designed specifically for the high-pressure applications they endure. By replacing the hose with a new one, you can ensure the safety and effectiveness of your pressure washer.

Remember, safety should always be a top priority. If you have concerns about the integrity of your pressure washer hose, it is best to consult a professional to determine the best course of action.

Understanding Pressure Washer Hoses

Pressure washer hoses play a crucial role in the overall performance of a pressure washer. These hoses are responsible for delivering the high-pressure water from the machine to the cleaning surface. Without a durable and reliable hose, the pressure washer would be ineffective.

There are several important factors to consider when understanding pressure washer hoses:

Hose Material:

The material of a pressure washer hose determines its strength and durability. Most pressure washer hoses are made from synthetic materials like rubber or PVC. Rubber hoses are known for their flexibility and resistance to kinks, while PVC hoses are lightweight and easy to handle. It is important to choose a hose material that can withstand the high-pressure water and various weather conditions.

The length of the pressure washer hose determines the range and mobility of the machine. Longer hoses allow for greater reach, which is beneficial for cleaning large areas or hard-to-reach places. However, longer hoses may also result in a decrease in pressure due to friction loss. It is important to find the right balance between length and pressure for optimal performance.

Hose Diameter:

The diameter of a pressure washer hose affects the water flow rate and pressure. Larger diameter hoses allow for greater water flow, resulting in higher pressure and cleaning power. However, larger hoses may also be heavier and less flexible. Smaller diameter hoses are lighter and more maneuverable but may have lower water flow and pressure. It is important to choose a hose diameter that matches the requirements of your pressure washer.

Hose Fittings:

The fittings on the pressure washer hose are crucial for connecting the hose to the machine and the spray gun. These fittings should be secure and leak-free to ensure proper operation. Common hose fittings include quick-connect couplers, M22 connectors, and threaded connectors. It is important to check the compatibility of the hose fittings with your pressure washer to avoid any issues.

Maintenance and Care:

To ensure the longevity of your pressure washer hose, proper maintenance and care are necessary. After each use, it is important to drain any remaining water from the hose and store it in a cool and dry place. Avoid kinking or crushing the hose, as this can lead to damage or leaks. Regularly inspect the hose for signs of wear or damage and replace it if necessary.

Overall, understanding the key aspects of pressure washer hoses is essential for choosing the right hose for your machine and ensuring its proper functionality. By considering factors like hose material, length, diameter, and fittings, you can optimize the performance of your pressure washer and achieve the best cleaning results.

Learn more about the nature and function of pressure washer hoses

A pressure washer hose is an essential component of a pressure washer system that connects the machine to the spray gun and nozzle. These hoses come in various lengths and diameters to suit different pressure washer models and applications. They are designed to withstand high-pressure water flow, often reaching hundreds or even thousands of pounds per square inch (PSI).

Pressure washer hoses are typically made of rubber, PVC (polyvinyl chloride), or thermoplastic materials. Each material offers different levels of durability, flexibility, and resistance to chemicals, abrasion, and extreme temperatures. Rubber hoses are popular for their flexibility and strength, while PVC and thermoplastic hoses are known for their affordability.

Some pressure washer hoses have reinforcement layers, such as braided steel wire or textile fibers, to increase their strength and resistance to kinks, punctures, and wear. These reinforcement layers help the hoses maintain their shape and withstand the high-pressure water flow without bursting or leaking.

When choosing a pressure washer hose, it is important to consider the maximum PSI rating of the hose and ensure it is compatible with the pressure washer unit. Using a hose with a lower PSI rating than the machine can lead to hose failure or reduced performance. Additionally, the hose should have the right length and connection type to properly fit the pressure washer and spray gun.

Caring for a pressure washer hose is essential to ensure its longevity and performance. After each use, it is recommended to flush out any remaining water, dirt, or debris from the hose to prevent clogs and damage. Storing the hose properly, away from direct sunlight and extreme temperatures, can also extend its lifespan.

| Material | Durability | Flexibility | Resistance |

|---|---|---|---|

| Rubber | High | High | Chemicals, abrasion, and extreme temperatures |

| PVC | Medium | Medium | Affordable option |

| Thermoplastic | High | High | Chemicals, abrasion, and extreme temperatures |

In conclusion, pressure washer hoses play a crucial role in the operation of pressure washer systems. Understanding the nature and function of these hoses can help users choose the right hose for their specific needs and maximize the efficiency and lifespan of their pressure washer system.

Introducing Flex Tape

Flex Tape is a revolutionary product that has been designed to provide a quick and effective solution for all your sealing and bonding needs. Whether you have a small crack or a major leak, Flex Tape can help you fix it in no time.

One of the key features of Flex Tape is its ability to create a watertight seal. It is made with a super-strong adhesive that forms a bond that is virtually indestructible. This means that you can trust Flex Tape to keep your surfaces dry, even under pressure.

How Does Flex Tape Work?

Flex Tape is made of a thick, flexible rubberized material that can stretch and conform to any shape or surface. This allows it to provide a tight seal that prevents water from seeping through. To use Flex Tape, simply cut it to the desired size, peel off the backing, and stick it to the surface. Press it firmly to ensure maximum adhesion.

What Can Flex Tape Be Used On?

Flex Tape is a versatile product that can be used on a wide range of surfaces and materials. It can be applied to both dry and wet surfaces, making it perfect for emergency repairs. You can use Flex Tape to fix leaks in pipes, hoses, roof tiles, and even inflatable items.

Not only is Flex Tape waterproof, but it is also resistant to extreme temperatures and UV rays. This makes it ideal for both indoor and outdoor use. It can withstand hot summers and freezing winters without losing its adhesive properties. Whether you need to repair a leaky hose or seal a crack in your roof, Flex Tape has got you covered.

In conclusion, Flex Tape is a reliable and effective solution for all your sealing and bonding needs. Its unique design and strong adhesive make it the perfect choice for quick repairs. So, why wait? Get yourself a roll of Flex Tape today and experience its incredible sealing power.

Explore the features and applications of Flex Tape

Flex Tape is a revolutionary adhesive tape that is known for its strong adhesion and waterproof properties. It is designed to seal and repair a wide variety of materials, making it a versatile tool for many different applications.

Features of Flex Tape

Strong adhesion: Flex Tape is known for its strong adhesive properties. It is designed to create a tight bond with a variety of surfaces, including plastic, metal, wood, and more. This strong adhesion ensures a long-lasting repair and prevents leaks and other damage.

Waterproof: One of the key features of Flex Tape is its waterproof nature. It is designed to create a watertight seal, making it perfect for repairing leaks in pipes, water tanks, and other water-related applications. Its waterproof property also makes it suitable for use in outdoor and marine environments.

Flexible: Despite its strong adhesive properties, Flex Tape remains flexible. This flexibility allows it to conform to irregular surfaces and move with the material it is applied to. This makes it perfect for sealing cracks, gaps, and holes in various materials.

Applications of Flex Tape

Repairing leaks: Flex Tape is commonly used for repairing leaks in various plumbing systems, including pipes, hoses, and water tanks. Its strong adhesive and waterproof properties make it an effective solution for preventing water damage and avoiding costly repairs.

Sealing cracks and gaps: Flex Tape can be used to seal cracks, gaps, and holes in a variety of materials, including plastic, metal, and wood. Its flexibility allows it to conform to irregular surfaces and create a tight seal.

Emergency repairs: Flex Tape is also a popular choice for emergency repairs. Its strong adhesion and waterproof properties make it a reliable solution for quick fixes in situations where immediate action is needed, such as during camping trips or in emergency plumbing repairs.

Outdoor and marine applications: Flex Tape’s waterproof nature and durability make it ideal for outdoor and marine applications. It can be used to repair and reinforce items such as tents, boats, and inflatables, ensuring they remain watertight and functional even in harsh conditions.

Overall, Flex Tape is a versatile adhesive tape that offers strong adhesion, waterproofing capabilities, and flexibility. Its wide range of applications makes it a handy tool for various repairs and emergency situations.

Testing Flex Tape on Pressure Washer Hoses

Pressure washer hoses are subjected to high levels of water pressure, which can lead to wear and tear over time. Many people wonder if Flex Tape, a popular adhesive tape known for its strong sealing properties, can be used to repair pressure washer hoses.

To test the efficacy of Flex Tape on pressure washer hoses, we conducted a series of experiments. First, we identified a hose with a small leak and applied Flex Tape tightly over the affected area, ensuring proper adhesion. We then reattached the hose to the pressure washer and tested it under varying water pressure levels.

The results were impressive. Flex Tape formed a strong, watertight seal on the pressure washer hose, effectively stopping the leak. It adhered firmly to the surface of the hose, even when exposed to the high water pressure. We tested it for an extended period, and the tape continued to provide a reliable seal without any signs of failure.

Flex Tape is designed to withstand extreme conditions, including exposure to water, making it an ideal solution for repairing pressure washer hoses. Its adhesive properties enable it to bond strongly to the hose material, preventing any further damage or leaks.

However, it’s important to note that Flex Tape should be applied correctly for optimal results. The surface needs to be clean and dry before applying the tape, and it should be wrapped tightly around the affected area, ensuring there are no gaps or creases. Following these instructions will improve the tape’s sealing capabilities.

In conclusion, Flex Tape is a viable solution for repairing pressure washer hoses. Its strong adhesive properties and ability to withstand high water pressure make it an effective choice for sealing leaks. By following the proper application techniques, users can expect durable and long-lasting results. It’s always a good idea to test the repaired hose under various conditions to ensure the tape’s effectiveness.

Find out how Flex Tape performs when used on pressure washer hoses

Pressure washer hoses can often experience wear and tear over time, leading to leaks and reduced performance. Flex Tape is marketed as a durable and waterproof solution for fixing a variety of household and outdoor items, but how does it perform when used on pressure washer hoses?

Many users have turned to Flex Tape as a potential solution for repairing pressure washer hoses. The adhesive backing is designed to create a strong bond, while the flexible rubber material is meant to provide a long-lasting and waterproof seal.

Does Flex Tape work on pressure washer hoses?

The results may vary depending on the specific circumstances and the condition of the hose. Some users have reported success with using Flex Tape to temporarily repair small leaks or cracks in their pressure washer hoses. The adhesive bond and waterproof nature of the tape can effectively stop leaks and allow the hose to continue functioning properly.

However, it is important to note that Flex Tape may not provide a permanent fix for more extensive damage or larger holes. The pressure generated by a pressure washer can be quite substantial, and the tape may not be able to withstand the high levels of force over an extended period of time. Additionally, the flexibility of the hose can put stress on the tape, potentially causing it to peel or detach.

Tips for using Flex Tape on pressure washer hoses:

- Prepare the surface: Clean and dry the hose before applying Flex Tape to ensure a strong bond.

- Cut appropriately: Use sharp scissors to cut the tape to the desired size and shape, allowing for any necessary overlapping or wrapping around the damaged area.

- Apply evenly: Press the tape firmly onto the hose, ensuring that it adheres securely and forms a tight seal.

- Allow time to cure: Give the tape sufficient time to adhere and create a strong bond before using the pressure washer again.

- Monitor and reapply if necessary: Regularly check the repaired area for any signs of peeling or detachment. If needed, clean the hose, remove any old tape, and apply new Flex Tape.

In conclusion, while Flex Tape may offer a temporary solution for minor leaks or damage to pressure washer hoses, it may not withstand the long-term pressure and stress generated by the equipment. For more extensive or permanent repairs, it is recommended to consult a professional or consider replacing the hose altogether.

Questions and answers

Will Flex Tape work on a pressure washer hose?

Yes, Flex Tape can be used to repair a pressure washer hose. It is designed to create a watertight seal and can withstand high levels of pressure.

Can Flex Tape fix a hole in a pressure washer hose?

Yes, Flex Tape is specifically designed to fix holes and leaks. It can create a strong bond and provides a long-lasting solution to repair a pressure washer hose.

What is Flex Tape made of?

Flex Tape is made of a strong, rubberized material that is capable of sealing leaks and creating a waterproof barrier.

Is Flex Tape easy to use?

Yes, Flex Tape is easy to use. Simply cut the tape to the desired size, peel off the backing, and apply it to the damaged area of the pressure washer hose. Press firmly to ensure a secure bond.

Can Flex Tape withstand high water pressure?

Yes, Flex Tape is designed to withstand high water pressure and can effectively seal leaks in a pressure washer hose.

Recent Posts

-

How To Connect Soap To Honda Pressure Washer

June 28, 2024 -

A To Z Pressure Washing Scam

June 27, 2024 -

How To Pressure Wash Your Home With A Garden Hose

June 27, 2024 -

Where Can I Buy Honda Pressure Washer Parts

June 25, 2024